Full-service Metal Forming and Manufacturing

Exceptional Service and Quality

35,000 square feet of machining excellence serving the mid-Atlantic region. For over 36 years, AMT has been the first choice for machining services in the Mid-Atlantic region for one-piece jobs to small shops all the way to major manufacturers with an international presence. Our Virginia Beach, VA manufacturing center features over 16,000 sqft of conditioned machining space, 8,000 sqft of material handling and fabrication, and an additional 11,000 sqft for large service applications.

Contact Us

One call. One solution.

On-Time and On-spec.

We can handle all your manufacturing and sheet metal needs.

Design. Build. Deliver.

State-of-the-art Laser Cutting

Today laser cutting is one of the most widespread material processing techniques. Compared to mechanical tools (shearing, punching, milling, etc.), the laser has many benefits including material flexibility, no part distortion, superior accuracy, AND NO TOOLING COST.

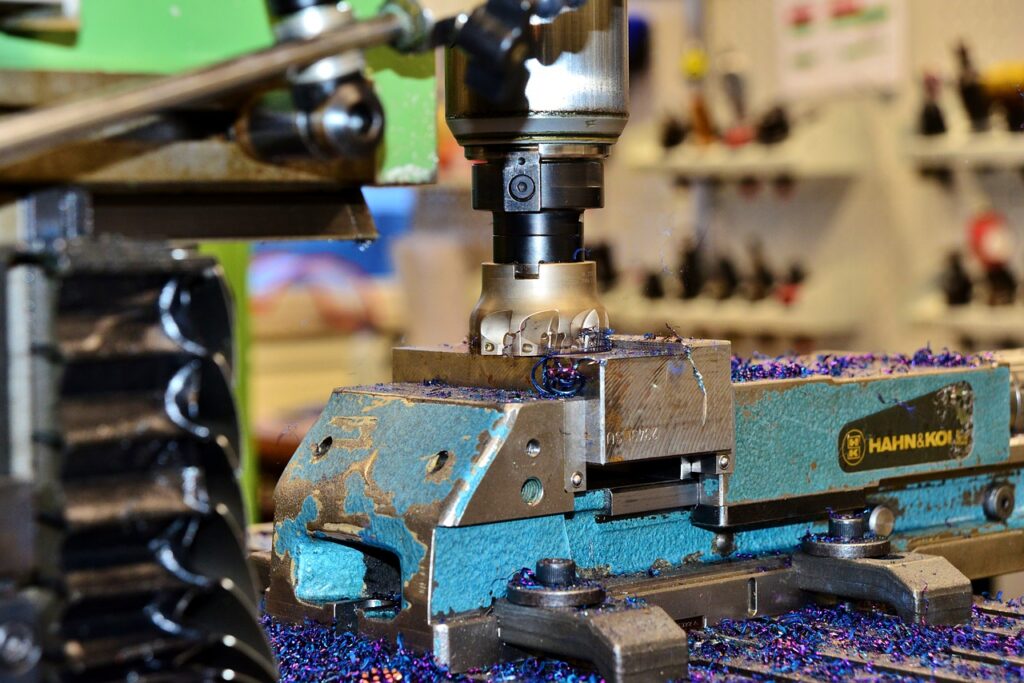

CNC Machining Services

Many designs are completed to exacting standards using CAD/CAM engineering software. Using AMT’s state-of-the-art CNC services to produce your part makes perfect sense! AMT is a full-service CNC machining facility featuring CNC-controlled Saws, Mills, and Turning machines.

Conventional Machining

Some jobs just need a master machinist’s touch. Our complete, full-service, conventional machine shop can help design and prototype the parts you need and make repairs necessary for your equipment. AMT’s master machinists have the tools and experience to make your parts or repairs to spec and on time.

Fabrication Services

AMT offers complete fabrication services. From CAD/CAM engineering through finished goods assembly, we can completely design, cut, weld, and assemble your part. We offer complete welding services, including MIG, TIG, and 3-phase spot welding. We have certified welders qualified in steel and aluminum welding.

Sheet Metal Manufacturing

AMT is a complete sheet metal manufacturing facility. From raw-material to finished parts, AMT has the equipment, skill, and experience for all your sheet metal manufacturing needs. From laser to press brake, shearing or notching, and finished with certified welding and assembly–we have you covered!

Trust us, we've already done it

AMT has seen and done it all over our last 37 years. We are a complete machining and fabrication job shop that can handle all your special needs. We have on-staff mechanical engineers and full CAD/CAM designers with experience in prototype design and execution.

State-of-the-art Laser Cutting

CNC Laser Services

Today laser cutting is one of the most widespread material processing techniques. Compared to mechanical tools (shearing, punching, milling, etc.), the laser has many benefits, including material flexibility, no part distortion, superior accuracy, AND NO TOOLING COST.

-

- NO EXPENSIVE TOOLING

- Capacities up to:

3/4″ steel up to 5′ x 10′ sheets

1/2″ clean-cut stainless steel

3/8″ aluminum

1 1/2″ non-metallic material - Positioning accuracy +/- 0.00039/20″

- Complete material handling, including delivery services

Computer Numerical Control (CNC)

CNC Machining Services

Many designs are completed to exacting standards using CAD/CAM engineering software. Using AMT’s state-of-the-art CNC services to produce your part makes perfect sense!

AMT is a full-service CNC machining facility featuring CNC controlled Saws, Mills, and Turning machines:

-

- CNC Milling: Mazak Vertical Milling 3-Axis. 26″x80″ max table size

- CNC Turning: Mori Sieki 4-Axis turning with live tooling

- CNC Mitre Sawing: up to 20″ x 20″ steel

AMT has the tools and the skills to turn your designs into products. In addition to making your product to exacting standards, our CNC capabilities allow us to repeat that process scaling all the way to Just-in-Time production schedule capabilities. From 1 to 1000 or more, AMT is your choice in CNC machining.

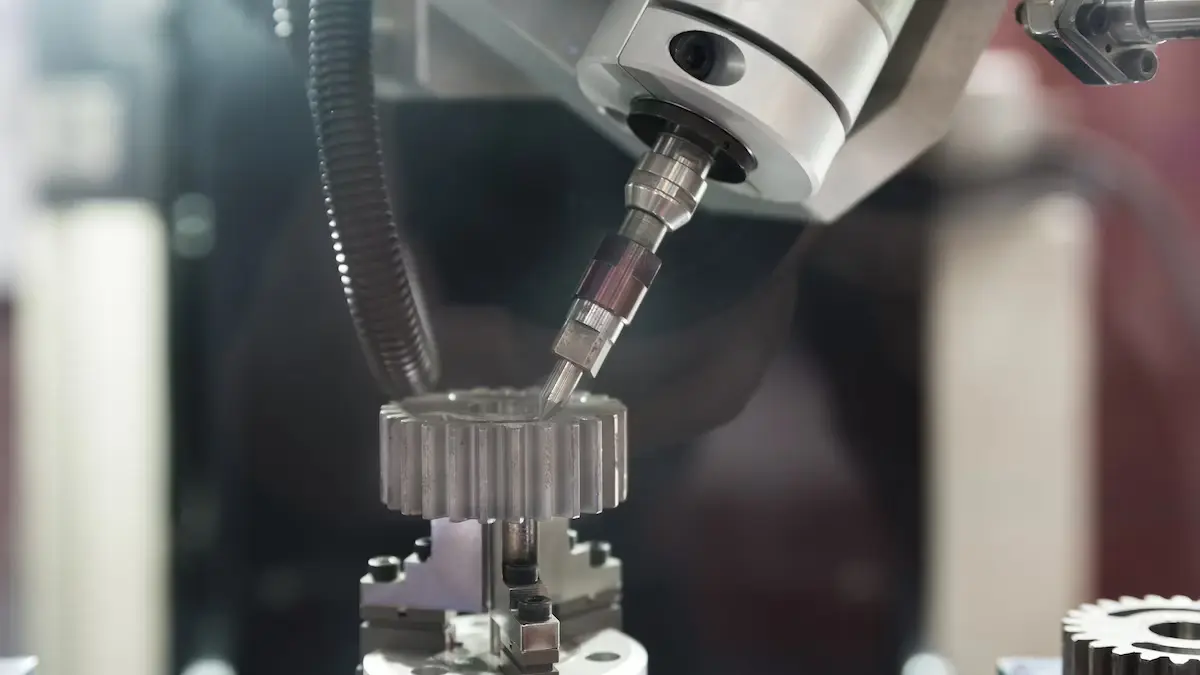

Master Machinist with Decades of Experience

Conventional Machining

Our complete, full-service, conventional machine shop can help design and prototype the parts you need for your business. We can also do any repairs necessary for your equipment. AMT’s master machinists have the tools and experience to make your parts or repairs to spec and on time.

AMT has a complete conventional machining center with:

-

- Conventional milling (9′ x 30″ tables)

- Conventional turning (27″ swing x 8′ centers)

- Surface grinding (6″ x 18″ table)

- Sawing (Fully automatic 18″ x 18″)

- Sawing Verticle up to 36″ throat

- Hydraulic Shearing (1/4″ x 120″)

- Welding (Mig/Tig) Aluminum, Stainless, and Steel (NavSea Certified)

- Spot Welding – 200KVA 3 phase (Steel and Aluminum)

- Inspection to MIL-I-45208

Let our machinists ‘turn’ out the parts you need. Accurately and efficiently.

From CAD/CAM through finished goods assembly

Complete Fabrication Services

AMT offers complete fabrication services. From CAD/CAM engineering through finished goods assembly, we can completely design, cut, weld, and assemble your part. We offer complete welding services, including MIG, TIG, and 3-phase spot welding. We have certified welders qualified in steel and aluminum welding.

Whether you need a part or a complete component assembly, AMT Can handle your needs:

-

- Custom trailers

- Commercial components

- Marine components, including specialized hulls

- Food service equipment

- Public Safety use equipment

- Custom building components, including frames and catwalks

AMT can fabricate your specific part to exacting standards and whatever certification processes you require.

From Raw-material to Finished Parts

Sheet Metal Manufacturing

-

AMT is a complete sheet metal manufacturing facility. From raw-material to finished parts, AMT has the equipment, skill, and experience for all your sheet metal manufacturing needs.

Our sheet metal services include:

- Multiple lasers

- 3 full CNC press brakes

- Shearing

- Notching

- Assembly

- Welding (certified)

More than a Machinists Touch

Advanced Services, Endless Possibilities

Advanced Machine and Tooling Inc. is a complete machining and fabrication job shop who can handle all of your special needs as well as bare-metal machining.

Full CAD/CAM Services

With several CAD/CAM designers on staff, AMT can take your sketch, blueprint, or Crayola design and turn it into a precision CAD drawing. Have your own CAD/CAM file for your part? Our experienced engineers will review your design and make sure that when it is finally sent to our computer controlled machines, your part will be produced accurately.

Assembly

AMT’s experienced staff can do more than just produce your parts. AMT can assemble your parts into your finished product with the same precision they are made with. Having AMT deliver completed assemblies to you saves time and simplifies your business.

Prototype Design

At AMT we build many prototypes. Many customers have an idea and want to see one or two to do further testing with. AMT can work with you to produce your part prototype and help you refine your design.

Single Part Production

Many companies come to AMT for single parts. These may be replacements for parts no longer available on the commercial market or one time projects. AMT will be glad to work with you to produce your part in a timely and cost efficient manner.

JIT Scheduled Production

At AMT, we use JOBBOSS software to schedule and manage customer jobs. This combined with our large material handling capabilities and extensive CNC machining centers makes AMT the perfect partner for your JIT process. AMT is able to schedule and deliver your parts as you need them, reducing your inventory management, overhead and costs.

We can tackle all of your needs:

-

-

- Dynamic Laser cutting – up to 5’ x10’ sheet capacity

- Precision Multi Axis CNC Machining

- Prototype and Contract Production Run Manufacturing

- NAVSEA Certified Welding

- Reverse Engineering

- Welding Fabrication – Carbon, Stainless, & Aluminum

- Precision sheet metal fabrication

- Onsite service – Welding, Repairing and restoring

- CAD Drafting and modeling with MasterCAM

- Build to print with tight tolerances

-

Reach out

Contact Us

Phone

757.518.1222

Address

5725 Arrowhead Drive

Virginia Beach, VA 23462

Advanced Machine, and Tooling, Inc.

5725 Arrowhead Drive

Virginia Beach, VA 23462

757.518.1222